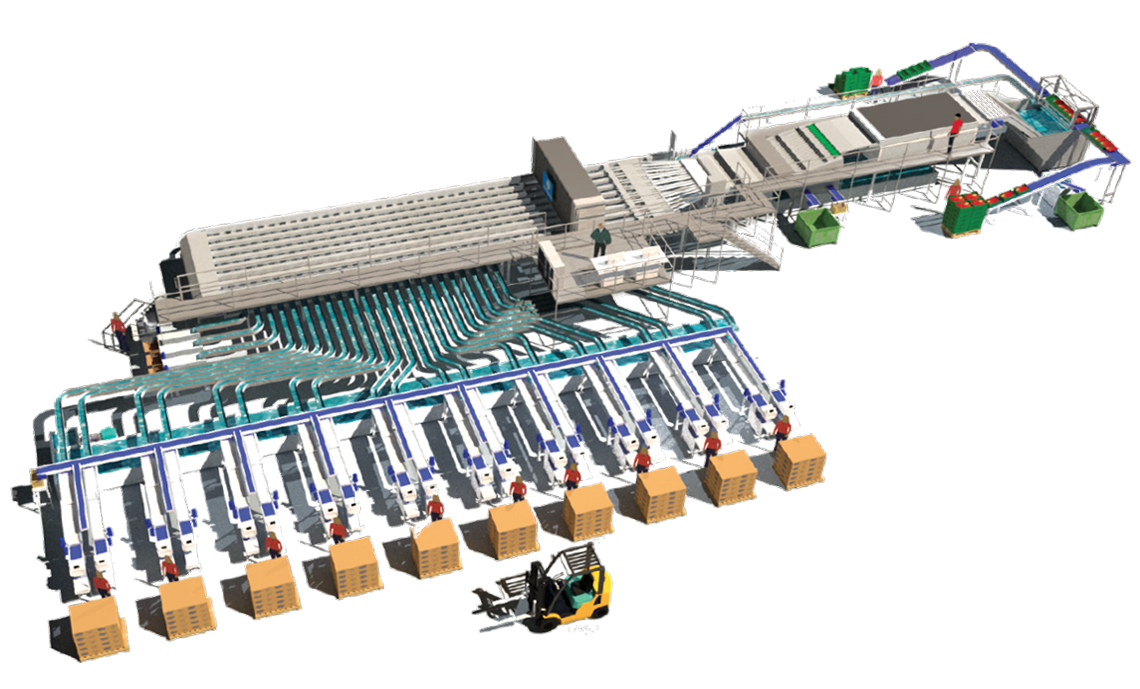

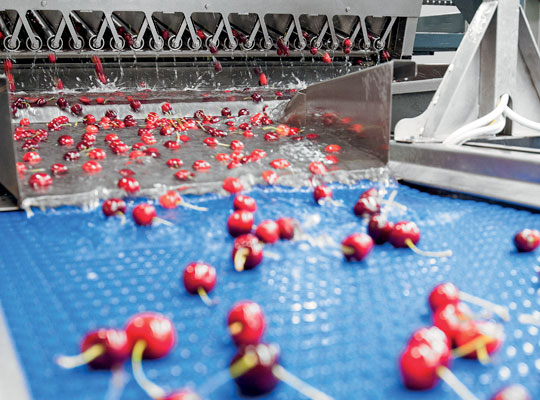

A notched modular elevator belt, the first part of which rests on the bottom of the tank, picks up the cherries and feeds them into the processing cycle. The elevator belts are equipped with a tray at output to help avoid possible damage to the fruit during falling.

Cherry Sorting Solution

The first step in each processing line is the transfer of products coming from the harvest. For cherries, this must be performed in an extremely delicate manner and, for this reason, they are sent into tanks with water at a temperature controlled by means of hydrocooling systems.

Crate submerger

This system makes it possible to carry out the entire product emptying phase in a fully automated manner. The system is composed of a feeder belt with adjustable guides, a modular accumulation belt, a submerger which submerges the crates into the tank below as it rotates, and a slide for evacuating empty crates.

Water bins feeding

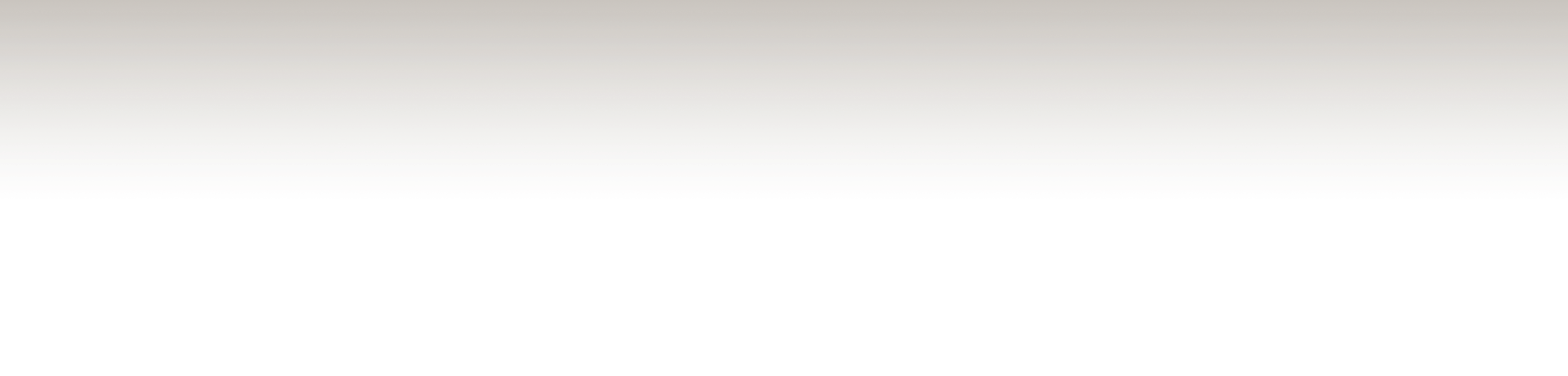

Set of machines designed to meet the needs of big production. Transport, destacking, submersion with rotating drum, empty bin pick-up, stacking and exiting transport. The entire system is managed by a practical touch screen, from where operators can make all the adjustments necessary to optimise the product transfer process.

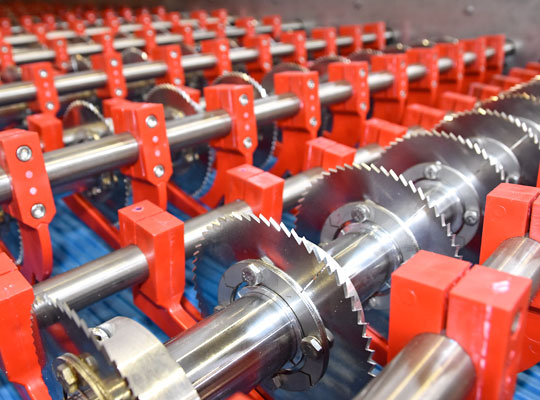

This machine, composed of a belt for feeding in water of the product to the blades and a collection tank, performs a very important function in cherry processing: separation of the clusters. The systems for adjusting the height of the belt and, consequently, of the fingers can be automatic or manual; this machine optimises separation of the clusters according to the length of the stems.

Suitable for the pre-selection of cherries, eliminating undersized fruit and waste, benefiting the sorting process. Equipped with dual motorized adjustment of the width of the rollers, which can be controlled electrically via touch screen for easy and intuitive use

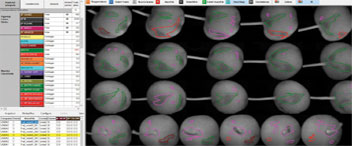

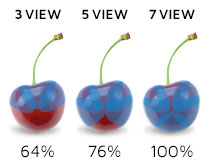

The careful selection of products is carried out by means of latest-generation vision systems, which make use colour and infra-red cameras managed by a complete and user-friendly software.

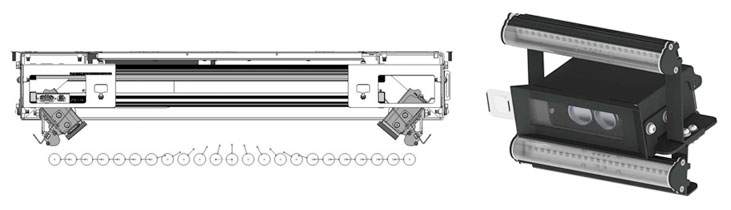

“InVision Total View” is the new technology for classifying cherries. For the first time in the world, it is possible with this system to detect 100% of the surface of the fruit and obtain very high definition images, thanks to the two new pairs of cameras set in strategic positions and to the new powerful lighting of additional LEDs.

The hardware management software has an easy-to-use interface that does not compromise performance and that also uses the latest Compac software features, such as “machine learning” and SmartMapTM and SmartSkinTM, which provide better detection and categorisation of defects.

It is possible to detect all the typical cherry defects on 100% of the surface of each fruit, such as soft, hailed, suzuki, bruising, splits, mould, holes, welts, doubles (stem).

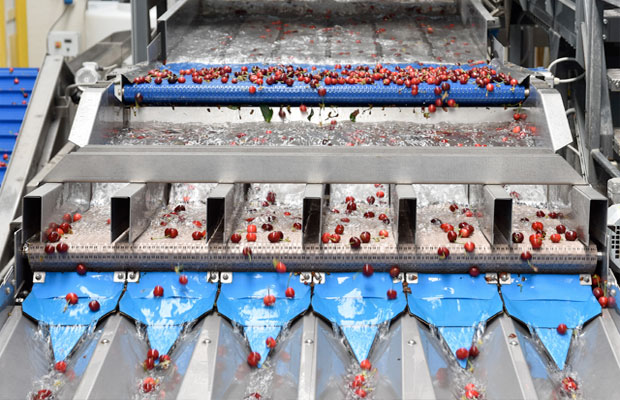

The heart of a line is the sorting machine, which selects cherries based on colour, shape, size and defects.

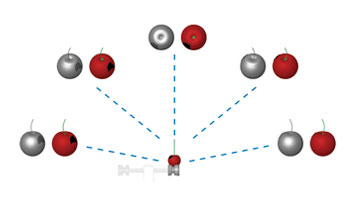

The Compac Small Fruit Sorter (SFS) is an electronic sorter designed to select small products such as cherries and cherry tomatoes. Using the Compac InVision system, the SFS selects products by size, shape, colour and external quality. The SFS is available with 1 to 16 channels in multiples of two, meeting the needs operators, from the smallest to the biggest. For higher production, larger warehouses can use multiple side-by-side sorters, all controlled by the same computer. The maximum speed of the SFS is 30 trolleys per second and a capacity of approximately 600Kg/hour per line, working at a speed of 1800 roller per minute per lane and an average product size of 28 mm.

MAIN FEATURE

- Dynamic lane balance; for uniform sorter filling;

- “V” belts for correct product alignment;

- Roller design that rotates products for InVision inspection;

- Air blower that guarantees gentle expulsion of delicate products.

The installations for big production instead use special collection channels with controlled-temperature water, for the passage of selected products exiting from the sorter to the packing benches.

Designed for the packaging of products processed in water, especially cherries, this bench guarantees the correct posture of the operator by avoiding disjointed movements. It consists of an initial conveyor belt (dewatering), which favors the dripping of the water allowing the processing of the dry product and the passage of waste into the water. Conveyor belts for last manually check are connected to subsequent machines, usually box fillers.

The final package is the showcase for every customer, and our filling systems are designed to be extremely delicate so as not to allow any cherry to ruin a pack and therefore the image of our client.

Manual filling system

For small production, packing of the selected product is performed manually. The products exiting the sorting machine are conveyed by means of belts onto tank packing benches equipped with an openable door to facilitate manual filling of the packages.

Semi-automatic filling system

This system is composed of a machine that facilitates semi-automatic bulk bin filling, using a crate finishing system to guarantee maximum precision in reaching the desired weight by means of a certified load cell. It is equipped with a touch screen from where it is possible to manage all the parameters of the packages to be filled.

Automatic filling system

Suitable for large production, this system allows bulk filling with automatic crate changeover. This machine, controlled by a software that can communicate with the sorter, is composed of two stations: one for filling and one for finishing, to ensure maximum precision of reaching the set weight by means of a certified load cell. It can be adjusted to process different size crates and is also equipped with a touch screen from where it is possible to manage all the parameters of the packages to be filled.